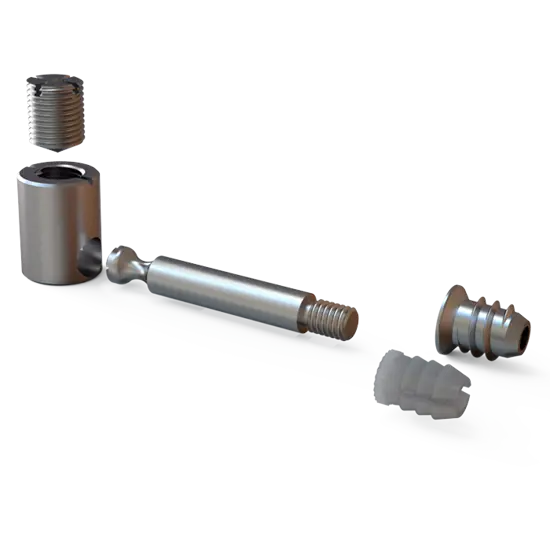

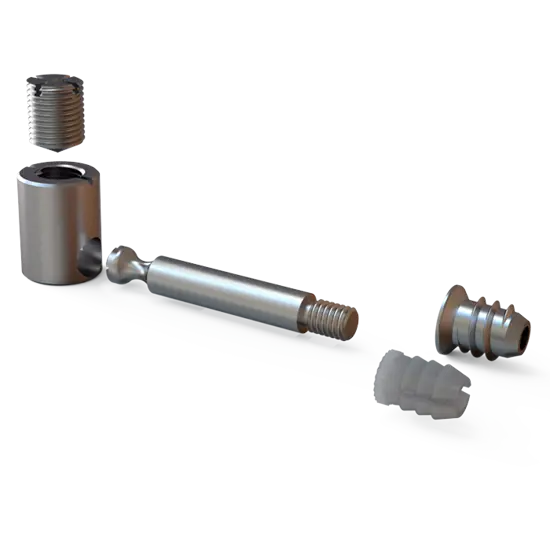

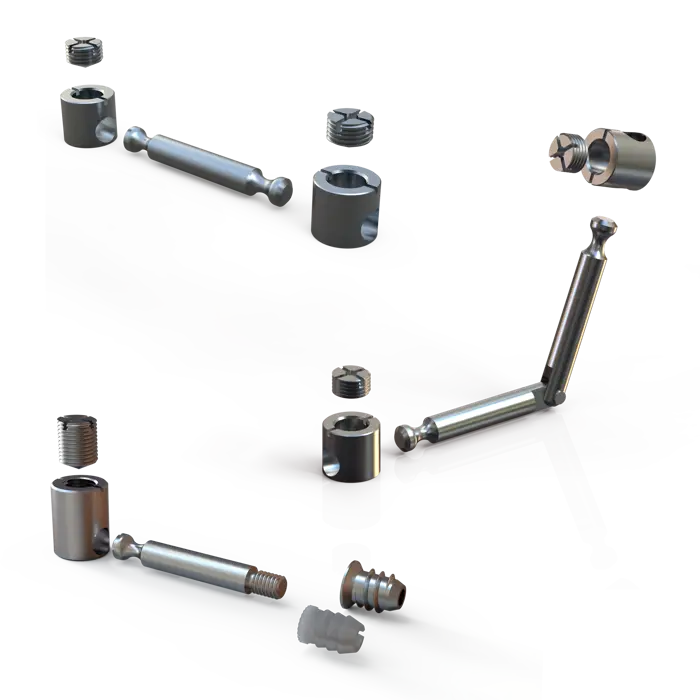

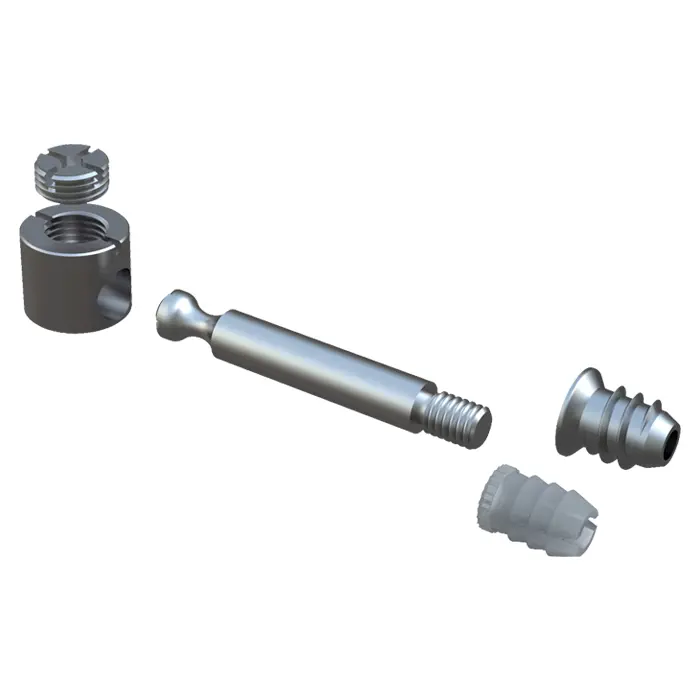

Fortefix is designed to make bolts, bodies, grub screws, puller.

Fortefix body is manufactured from steel by machining and has a cylindrical body. Its diameter is 15mm,. Fortefix and grub screw are produced in different sizes in accordance with the thickness of the wood panel. On the upper part of the Fortefix body, there is an M10 threaded grub screw cavity. On its lateral surface, there is a hole (opened with a tolerance suitable for the shaft diameter) that the fortefix shaft can enter. Thus, the Set screw, which is mounted from the upper part of the Fortefix body, is provided to vertically contact the shaft that enters freely from the lateral surface. The position of the Fortefix body (its direction relative to the shaft) during assembly can be adjusted from the top with a flat screwdriver.

Fortefix grub screw is produced from steel by machining. The upper part of the setscrew has a Phillips

head and screwing can be done using flat and Phillips screwdrivers. The tip of the setscrew is produced

with an angle of 115 degrees and is compatible with the radius concave surface on the neck of the

fortefix shaft. The inclined contact surface created between the two angles allows the shaft to move and

pull to occur with the pressure exerted by the grub screw on the shaft. The pulling and joining made

by the metric threaded grub screw do not loosen. The level of bond strength continues throughout

the use of the furniture.

Fortefix bolt is produced from steel material by machining. Shafts, which have a cylindrical body, are the part that provides the connection between the panels. metric threaded straight shafts, table connection shafts, single-sided shafts, single-sided jointed shafts, double-sided jointed shafts, articulated stop shafts, 90-degree shafts, double-sided shafts, double-sided circlip shafts.