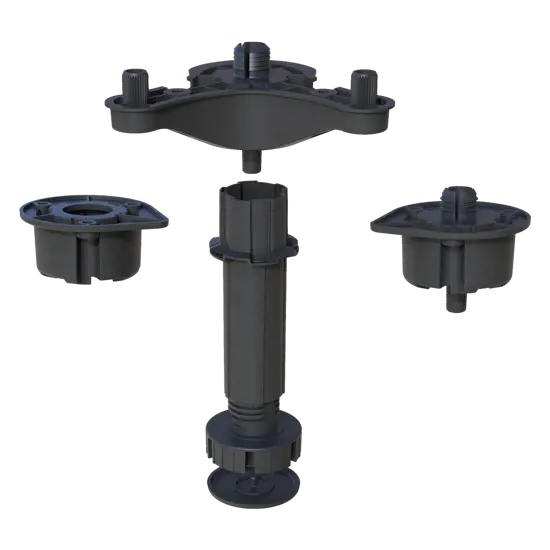

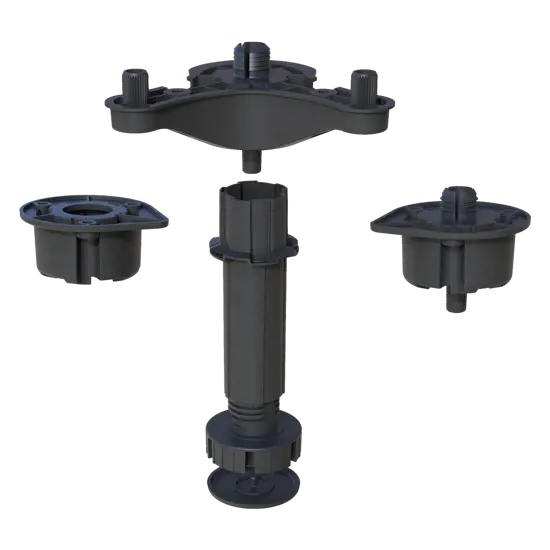

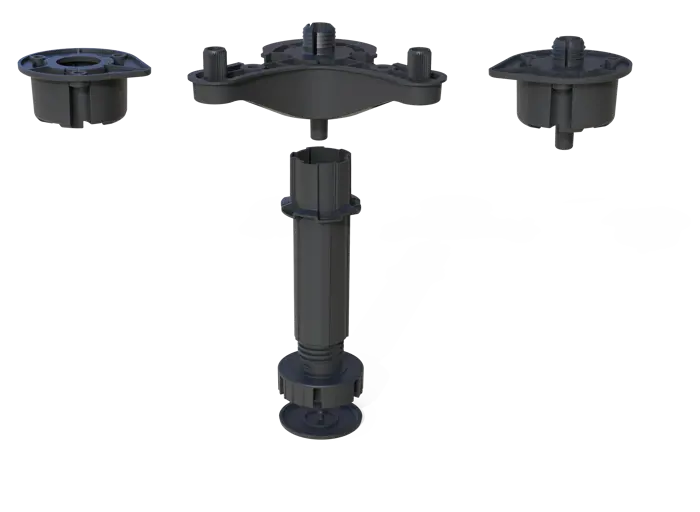

Hector plinth leg is a module foot system consisting of Plinth Pipe, Pingo, clip, Plinth Pingo Plug

and plinth top Connection parts. Loading capacity is 150 kg per foot, 3 or more feet max. While

the 450 kg Box Furniture is assembled and shifted, the plinth foot, pingo, keeps its position securely

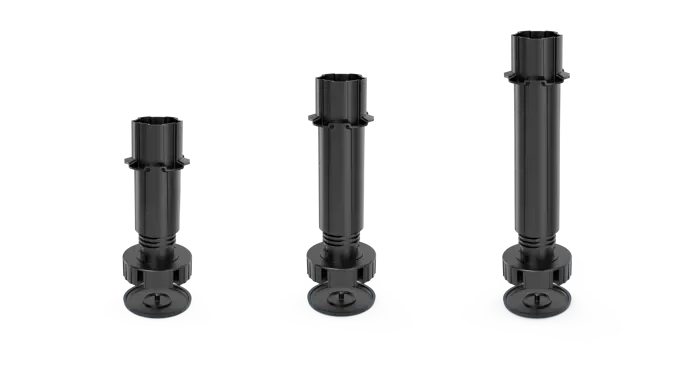

in the upper connection. All types of the hector, which has 3 dimensions, 100mm, 120mm, 150mm,

have the possibility of -5mm and +25mm height adjustment by adjusting the pingo. Rotation of the

pingo is comfortable and easy as the plinth pipe and the plinth upper connection are vertically

interlocked with five channels. All types of hector, which has 3 dimensions, have the possibility of

-5mm and +25mm height adjustment by turning the pingo. Rotation of the pingo is comfortable

and easy as the plinth pipe and the plinth upper connection are vertically interlocked with five channels.

104-01-65 Hector plinth is self-fixed on the top, and after it is placed into the hole drilled in the size of the dowel, the hammer action with a hammer ensures its fixing and assembly. Screwing should be done later, taking into account the nail direction.

104-0,1-67 Hector pin plinth top connection, especially with hammer-in dowels, which can be exposed

to cross loads and are designed to meet high vertical and horizontal transportation needs

(especially island type modules), and the mounting position is determined by self-plugging dowels.

It is the upper module of the plinth with hammer pins, which provides a connection to the module before screwing.

104-01-66 The top connection to the plinth, which has a clawed structure that transfers the weight of the furniture to the bay window of the cupboard side upright, together with the bottom of the cabinet, The hole to be drilled on the bottom plate of the furniture, the hole to be drilled in the upper connection axis, and the screwdriver access hole to the plinth pingo, allowing height adjustment from within the furniture. allows us to achieve.

Base top connection suitable for the construction and module type of the furniture is preferred.

Pipe suitable for the desired plinth height is preferred. For height adjustment from within the

module, a hole must be drilled into the wooden bottom plate and a 104-01-66 hector base upper

connection must be used.

-5 and +25mm total 30mm height adjustment is possible

Other height adjustments will be made by manually turning the pingo. Dowel coded 104-01-65

(Ø15mm h:13mm) and Three-pin 104-01-67 (1x Ø15mm and h:12mm middle, 2x Ø10mm and

h:12mm dowels) plinth upper connections, in suitable diameters and intervals for dowels Requires

the hole process. we must fix the upper connections by driving the pins which are stable on

themselves. The hammering action is specially designed to achieve compression in the dowel with

controlled breaking at the point where the pin is located.

-5 and +25mm total 30mm height adjustment can be made by rotating the pingo by hand.

The plinth top mounting screw is related to the preferred wood panel thickness in furniture

construction. 3,5 and 4 series wood screws should be preferred. It should be mounted with one screw

in each screw hole. The furniture and base pair, whose assembly is completed, should be moved

by lifting, not by dragging. After the box furniture modules are placed in their positions in accordance

with the design, the height settings of the pingo are leveled according to the ground plane, and

uniform contact of the walls or modules with each other is ensured. After all modules are mounted to

each other or to the wall, the pingos of the plinth feet are checked for the last time. Make sure that

there is no loose and idle ping. The clips suitable for the preferred type of plinth material

(PVC, Aluminum, wood) are mounted by screwing to the inner part of the plinth or by inserting it

into the duct. The plinth clips are designed to be single and double. Single clips for 100-12Omm

plinth pipes, double clips for 120 and 150mm plinth pipes can be preferred. When the plinth pipe

length and plinth height increase together, a single clip cannot protect the vertical square of the

plinth, since the plinth weight increases. Another factor that triggers this situation is the distance

between the plinth legs, that is, the width of the modules is small and the plinth feet are used

frequently, in short, clip selection should be planned according to the location in every project.